Introduction

In the world of heavy industry, every metal component has a hidden identity: its heat number. This stamp on the metal is more than just a random sequence—it is the link between a finished part and the melt from which it was cast. For procurement engineers working on combined-cycle power plants, heat-number traceability is a vital tool to ensure that what you buy meets the chemical and mechanical requirements specified in your contracts. When a pressure part fails, the first question investigators ask is “What was its heat number?” This article will help you understand what heat numbers are, why they matter, and how to manage them in your supply chain.

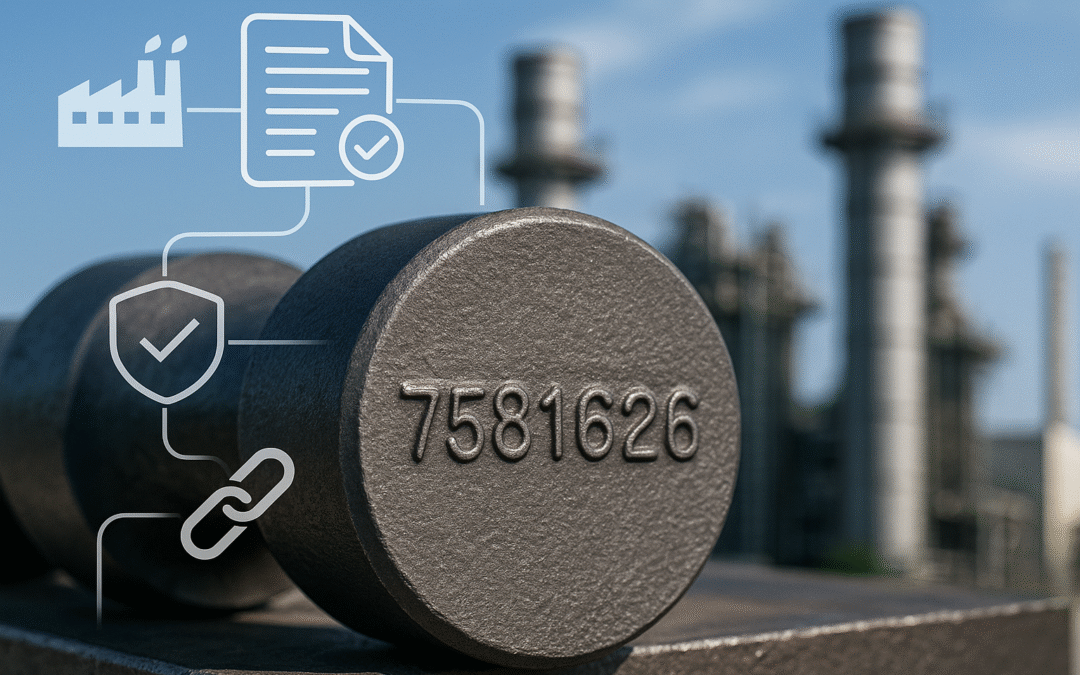

What Is a Heat Number?

A heat number is a unique identifier assigned to a batch of steel or alloy at the time it is produced in the mill. Each time steel is melted in a furnace, a “heat” of material is poured. When this melt is cast, the material is tested and its chemical and mechanical properties are recorded in a mill test report (MTR). The heat number is stamped onto the surface of ingots, plates, bars, forgings, or castings. Without this stamp, you have no way of knowing exactly which batch of metal you are dealing with. The number ties the physical product back to its test report and the production records at the mill. In high-risk applications like high‑temperature piping or pressure vessels, this stamp is your evidence that the material truly meets the grade.

Why Traceability Matters

Traceability is essential for legal compliance, quality assurance, and long‑term reliability. Specifications from ASME, ASTM, EN, and project-specific codes require that certain components have full traceability from the steel mill to the final installation. If a turbine casing or a header rupture occurs, regulators will ask to see the MTR and heat number trail. Without documentation, you may face costly replacement, penalties, or even criminal liability. Traceability also ensures that you can identify and recall products if a material defect is discovered. In the context of procurement, requiring heat numbers and proper certificates helps you avoid counterfeit or mismatched material and proves to your client that you take compliance seriously.

Heat Numbers vs. Lot Numbers

It is important to distinguish between a heat number and a lot number. A heat number identifies the specific melt from which the metal was produced. A lot number, on the other hand, is assigned by the manufacturer or stockist and may represent a smaller group of parts that were processed together. Lot numbers often mix material from different heats, especially if a stockist cuts plates or bars from multiple melts. If you receive parts with only a lot number stamped on them, you need to ask the supplier to show the heat numbers associated with each part within the lot. Otherwise, you cannot link the finished product back to its material certification.

Procurement Practices for Heat Number Traceability

As a procurement engineer, you need to ensure that your purchasing documents require heat-number traceability. Here are a few steps you can incorporate into your RFQs and purchase orders:

- Specify that all pressure and safety-critical items must be supplied with EN 10204 3.1 or 3.2 certificates. These certificates include specific test results for the actual batch and guarantee that independent inspectors have verified the data.

- Demand that each component be clearly stamped with its heat number. This stamp must be legible and preferably located near the identification plate or a permanent part of the component.

- Require that the supplier provide a list matching each component’s serial number or tag to its heat number and to the MTR. This prevents confusion if components are separated during shipping.

- Audit the supplier’s traceability system. When possible, inspect the warehouse or fabrication shop to ensure that they keep heat numbers intact and do not mix up parts from different heats.

- Include penalties for missing stamps or mismatched documentation. If a component arrives without a heat number or with an incorrect certificate, insist on replacement at the supplier’s expense.

Tools and Technologies for Managing Heat Numbers

In large projects, handling hundreds of heat numbers manually can be difficult. Modern tracking systems help you manage this data accurately:

- Barcode and QR Code Labels. Some suppliers now include a barcode or QR code along with the heat number. Scanning the code reveals the material grade, heat number, and MTR reference. This reduces human error and speeds up incoming inspection.

- Digital MTR Databases. Instead of storing paper copies, create a digital database of MTRs organized by heat number and component tag. This allows quick retrieval during audits.

- Enterprise Resource Planning (ERP) Integration. Many procurement departments integrate material traceability into their ERP systems. This connects purchase orders, goods receipts, and MTRs in one platform so you can see at a glance whether a heat number is approved and where the material has been installed.

- Blockchain Solutions. Emerging solutions use blockchain to create an immutable record of each heat and its journey through the supply chain. While still new, this technology promises to eliminate counterfeit certificates by making traceability records tamper-proof.

Maintaining Traceability Through Fabrication

Even if the mill provides proper certificates, traceability can be lost during fabrication. Welding, cutting, and assembly processes often remove the original stamps. To prevent this, instruct your fabricators to:

- Transfer heat numbers to new tags or maintain a traveler card that stays with the part throughout fabrication.

- Stamp or mark cut pieces and subassemblies before the original mark is destroyed.

- Keep a log of which pieces come from which heats and ensure welders trace filler materials as well.

- Provide updated certificates or weld maps that show how different heats were joined. Without this, the final assembly cannot be fully traced back to its original material properties.

Common Pitfalls and How to Avoid Them

Many traceability failures occur at the interfaces between different parties. Stockists may mix plates from different heats and deliver them under a single certificate. Fabricators may weld pieces from different heats together and only stamp the assembly once. Here are ways to mitigate these issues:

- Perform random checks during production. Compare heat numbers on parts with the documentation.

- Do not accept photocopies of MTRs without original signatures or digital certificates.

- Train your receiving inspectors to check heat numbers at incoming inspection rather than waiting until installation.

- Use a third-party inspector to witness stamping and review traceability logs at the supplier’s facility.

- If there is any doubt about a component’s heat number, reject it and request a replacement. Salvaging parts without proper identification often costs more in the long run.

Case Study: A Valve Mix-Up

Consider a combined-cycle plant that purchased a batch of safety relief valves. The purchase order required 3.1 certificates and heat number stamps. During installation, inspectors noted that two valves lacked heat numbers. The supplier insisted that the valves came from the correct batch and provided an MTR copy. However, further investigation revealed that the supplier had mixed inventory from two different heats. The MTR provided corresponded to one heat, but the undocumented valves were from another heat with slightly lower tensile strength. Because the heat numbers were missing, there was no way to prove which valves were which. The buyer rejected the entire batch, leading to delays and additional costs. If the supplier had properly stamped each valve and maintained a heat-to-serial-number log, the issue could have been resolved quickly. This case illustrates why stamping and documentation are essential for critical equipment.

Conclusion: Turning Traceability into Trust

Heat-number traceability may seem like a tedious administrative task, but it forms the backbone of quality assurance in high-risk industries. By ensuring that every component can be linked back to its material batch, procurement engineers protect their projects from hidden material defects and counterfeit products. Combined-cycle power plants operate at the edge of metals’ capabilities—keeping track of the “DNA” of each component ensures that you’re building on a solid foundation. If you need help setting up or auditing a traceability system, don’t hesitate to reach out. As an independent consultant, I specialise in bridging the gap between design requirements and supplier documentation. Together we can build a supply chain that is transparent, compliant, and trustworthy.